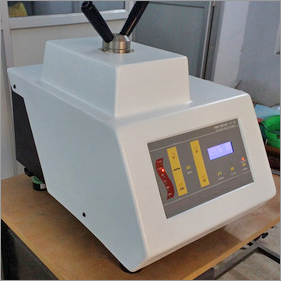

Spectro Table Top Polishing Machine

Spectro Table Top Polishing Machine Specification

- Number of Specimens

- Single specimen at a time

- Display Type

- Analog speed indicator

- Automation Grade

- Manual

- Operating Voltage

- 220 VAC

- Application

- Metallurgical specimen polishing for material analysis

- Equipment Type

- Table Top Polishing Machine

- Interface Type

- Manual controls

- Measuring Range

- Applicable to metallic, ceramic, and composite samples

- Humidity

- Up to 85% RH (Non-Condensing)

- Features

- Durable construction, anti-corrosive housing, variable speed, water inlet, easy disc mounting

- Frequency

- 50 Hz

- Specimen Size

- Up to 40 mm diameter

- Test Range

- Suitable for all metallographic specimens

- Hardness

- Suitable for high-hardness materials

- Power Supply

- 220V AC, 50 Hz, Single Phase

- Max Height

- Approx. 16 inches

- Mounting Type

- Table Top

- Response Time

- Instantaneous mechanical drive

- Port Size

- Standard tap water connection

- Accuracy

- High-precision mirror finish

- Temperature

- Up to 40C ambient

- Usage

- Metallurgical laboratory polishing

- Capacity

- Single disc operation

- Machine Weight

- Approximately 60 kg

- Test Speed

- 500 - 1400 RPM (Variable)

- Test Width

- 8 inch (Polishing Disc Diameter)

- Control Mode

- Manual

About Spectro Table Top Polishing Machine

Commercial Applications and Distinguished Features

The Spectro Table Top Polishing Machine is expertly crafted for commercial environments including research institutes, industrial metallurgical labs, and material analysis centres. Used for polishing metallic, ceramic, and composite specimens, it provides high-precision finishes essential for accurate evaluations. Its features include variable speed control, durable powder-coated structure, anti-corrosive body, low noise, water cooling inlet, and reliable manual controlsmaking it the preferred choice for demanding material preparation tasks.

Delivery Time, Sample Policy, and Supply Ability

Following Order Completion and finalized Proposal Amount, we strive for prompt dispatch and delivery of your Spectro Table Top Polishing Machine within standard industry timelines across India. Supply ability is robust for ongoing commercial projects, ensuring readiness for bulk or single unit orders. For quality assurance, sample policies are available upon proposal, enabling clients to assess machine performance before securing supply for larger orders.

FAQs of Spectro Table Top Polishing Machine:

Q: How does the Spectro Table Top Polishing Machine ensure user safety during operation?

A: The machine is designed with enclosed rotating parts, significantly minimizing the risk of accidental contact during use. This feature helps ensure operator safety in busy laboratory environments.Q: What specimens can be polished with this equipment?

A: The Spectro Table Top Polishing Machine is suitable for a wide range of metallographic specimens, including metallic, ceramic, and composite samples, supporting up to 40 mm diameter per specimen.Q: When can I expect delivery after placing an order?

A: Delivery is initiated promptly upon order completion and confirmation of proposal amount. Most orders are fulfilled within standard industry timelines, depending on location and supply volume.Q: Where is this machine commonly used?

A: This model is widely utilized in metallurgical laboratories, research centers, and quality control departments for specimen polishing and material analysis tasks.Q: What are the key benefits of its manual control and variable speed features?

A: Manual control and variable speed (5001400 RPM) allow users to adjust polishing conditions according to the unique requirements of each specimen, resulting in an accurate and repeatable mirror finish.Q: How does the water inlet contribute to laboratory operations?

A: The integrated water inlet provides efficient cooling during polishing, which helps prevent specimen overheating and enhances operational safety and finish quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing & Measuring Equipment Category

Foundry Sand Testing Equipment

Features : Corrosion resistant, Portable design, Robust construction

Humidity : Up to 85% RH

Application : Testing physical properties of foundry sand

Equipment Type : Foundry Sand Testing Equipment

Operating Voltage : 220V AC

Usage : Industrial, Laboratory

Magnetic Crack Detector Portable Yoke Kit

Features : Lightweight, easy to operate, high lifting capacity, rugged design

Humidity : 80% RH

Application : Weld inspection, surface crack detection, nondestructive testing (NDT)

Equipment Type : Magnetic Crack Detector Portable Yoke

Operating Voltage : 230V AC

Usage : Magnetic particle inspection (MPI), field and shop use

Carbon Determination Apparatus

Features : Corrosion resistant, double jacket combustion tube, quick heating, easy to operate

Humidity : Ambient

Application : Analysis of carbon content in ferrous or nonferrous metals, ores, alloys, and other materials

Equipment Type : Carbon Determination Apparatus

Operating Voltage : 230 V AC

Usage : Chemical analysis laboratory

Automatic Type Supermount Pneumatic Mounting Press

Features : Automatic operation, quick mold change, programmable timer, builtin safety lock, pressure adjustment

Humidity : 85% RH

Application : For hot mounting of metallographic specimen preparation

Equipment Type : Automatic Type Supermount Pneumatic Mounting Press

Operating Voltage : 220V

Usage : Metallurgical Laboratory Sample Preparation

|

SUPERTECH SCIENTIFIC & METALLURGICAL SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry