Metallurgical Consumables

Metallurgical Consumables Specification

- Test Range

- Depends on consumable type

- Equipment Type

- Metallurgical Consumables

- Humidity

- 10%-80% RH (operational)

- Automation Grade

- Manual/Semi-automatic

- Max Height

- Up to 120 mm (sample preparation)

- Display Type

- Analog / Digital (as applicable)

- Application

- Sample cutting, mounting, grinding, polishing, testing

- Interface Type

- Direct/manual use

- Frequency

- 50 Hz

- Accuracy

- 0.02 mm (typical for preparation)

- Temperature

- 10C-40C (operational)

- Operating Voltage

- 230 V AC

- Response Time

- Immediate (manual consumables)

- Port Size

- Standard Consumable Sizing

- Number of Specimens

- 1-3 per set

- Power Supply

- 220-240V, 50/60Hz

- Features

- High durability, consistent results, suitable for multiple metals

- Measuring Range

- Material specific

- Mounting Type

- Bench-mounted/handheld consumables

- Hardness

- Consistent with consumable material grade

- Resolution

- 0.01 mm (micrometer range)

- Specimen Size

- As per metallurgical standard (10x10x50mm, custom sizes available)

- Usage

- Metallurgical laboratories, Quality control

- Capacity

- Medium scale laboratory and industrial use

- Machine Weight

- 10-50 kg (varies by product type)

- Test Speed

- 0.2-2 mm/min (typical for preparation equipment)

- Test Width

- 10-30 mm

- Test Stroke

- Up to 150 mm

- Control Mode

- Manual / Semi-Automatic

- Color

- Black, grey, white (varies with consumable)

- Packaging Type

- Box / sealed packets

- Consumable Type

- Cutting wheels, abrasive papers, polishing cloths, mounting resins

- Surface Finish Achievable

- Mirror finish to 1 micron Ra

- Safety Compliance

- RoHS / CE Certified

- Material Compatibility

- Ferrous and non-ferrous metals

- Manufacturing Standard

- IS, ASTM, DIN as applicable

- Shelf Life

- 18-24 Months

About Metallurgical Consumables

Personalise your laboratory operations with invincible Metallurgical Consumables, tailored for both ferrous and non-ferrous materials. Benefit from instant savings through cost-effective solutions designed for sample cutting, mounting, grinding, polishing, and testing. Achieve distinguished results with surface finishes from mirror polish down to 1 micron Ra. Available in imposing black, distinguished grey, and classic white, each product complies with strict RoHS and CE standards. Boxed or securely sealed, these consumables offer consistent accuracy (0.02mm), long shelf life (18-24 months), and adaptable usability for medium scale labs or industry. Exporter, manufacturer, supplier, and service provider in India.

Features, Advantages and Usage of Metallurgical Consumables

These consumables are bench-mounted or handheld, ensuring versatility for varied laboratory setups. With manual or semi-automatic control, each machine delivers medium-scale capacity, high durability, and precise results. They are used extensively for sample preparation and quality control in metallurgical laboratories, achieving accurate cuts and mirror finishes. The advantage lies in ease of use, reliable performance, and compatibility with a variety of metals, making them indispensable for research and industrial testing.

Certifications, Sample Exchange, and Packaging Details

Our metallurgical consumables are RoHS and CE certified, manufactured under IS, ASTM, and DIN standards. Swift exchange and quick dispatch minimize expenditure and ensure prompt service. Samples are available for trial; packaging includes box and sealed packets, promoting safe transport and extended shelf life. Each product is rigorously tested before shipping, providing confidence and reliability with every purchase and exchange.

Features, Advantages and Usage of Metallurgical Consumables

These consumables are bench-mounted or handheld, ensuring versatility for varied laboratory setups. With manual or semi-automatic control, each machine delivers medium-scale capacity, high durability, and precise results. They are used extensively for sample preparation and quality control in metallurgical laboratories, achieving accurate cuts and mirror finishes. The advantage lies in ease of use, reliable performance, and compatibility with a variety of metals, making them indispensable for research and industrial testing.

Certifications, Sample Exchange, and Packaging Details

Our metallurgical consumables are RoHS and CE certified, manufactured under IS, ASTM, and DIN standards. Swift exchange and quick dispatch minimize expenditure and ensure prompt service. Samples are available for trial; packaging includes box and sealed packets, promoting safe transport and extended shelf life. Each product is rigorously tested before shipping, providing confidence and reliability with every purchase and exchange.

FAQ's of Metallurgical Consumables:

Q: How do I select the right metallurgical consumable for ferrous and non-ferrous materials?

A: Selection depends on your testing needs and material compatibility. Check product specifications for suitable consumable types such as cutting wheels, abrasive papers, and polishing cloths designed for both ferrous and non-ferrous samples.Q: What safety and quality certifications do these consumables carry?

A: All consumables are RoHS and CE compliant, and manufactured under recognized standards like IS, ASTM, and DIN, ensuring optimal safety and consistent quality.Q: When is it recommended to exchange consumables in a laboratory setup?

A: Consumables should be exchanged after their designated shelf life (18-24 months) or following significant wear from repeated use, maintaining accuracy and reliable performance for sample preparation.Q: Where are these metallurgical consumables most effectively used?

A: They are ideal for metallurgical laboratories, quality control departments, and industrial research settings, providing precision and reliability in cutting, mounting, grinding, and polishing tasks.Q: What is the process for requesting a sample, and how quickly is it dispatched?

A: You can request samples directly. After confirming requirements, quick dispatch is ensured, allowing fast evaluation and minimal expenditure before purchasing in bulk.Q: What benefit do these consumables offer in terms of surface finish?

A: They provide a distinguished mirror finish up to 1 micron Ra, ensuring precise sample preparation and superior results for metallurgical analysis.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Testing & Measuring Equipment Category

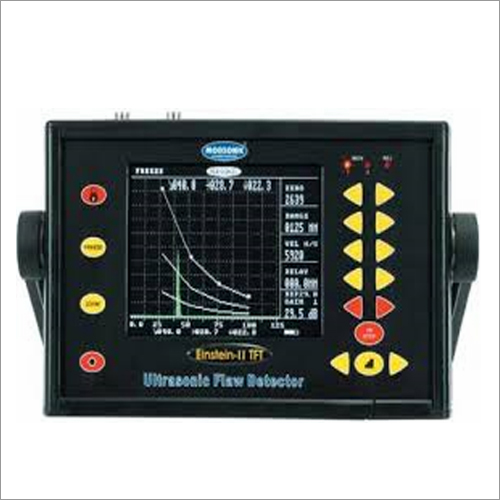

NON Destructive Testing Equipment (NDT)

Application : Flaw Detection, Weld Inspection, Structure Evaluation

Control Mode : Digital / Manual

Usage : Industrial, Laboratory

Accuracy : 1%

Resolution : 0.01 mm

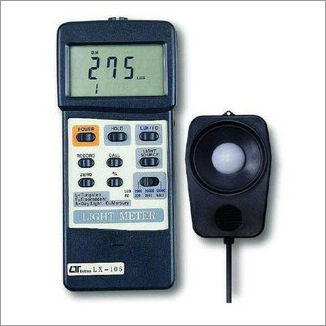

Lutron Lux Meter

Application : Light measurement for industrial, laboratory, and field use

Control Mode : Manual

Usage : Measurement of illumination

Accuracy : (5% + 2 dgt)

Resolution : 0.1 Lux

Inverted Microscope

Application : Laboratory

Control Mode : Manual

Usage : Laboratory

Accuracy : 1% %

Color : Any

Resolution : 5MP

|

SUPERTECH SCIENTIFIC & METALLURGICAL SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry