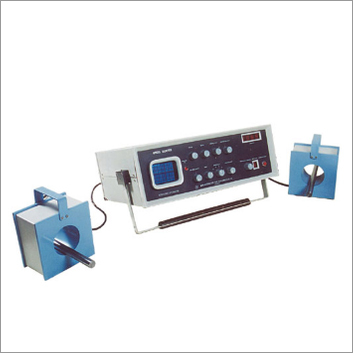

Eddy Current Sorter

Eddy Current Sorter Specification

- Port Size

- 8 mm (air inlet)

- Mounting Type

- Floor-standing

- Automation Grade

- Fully Automatic

- Display Type

- LCD Touchscreen

- Number of Specimens

- 1 at a time (batch sorting possible)

- Interface Type

- RS232/USB/Ethernet

- Frequency

- 10 kHz - 200 kHz

- Features

- High-speed detection, auto-rejection, user-friendly interface, support for multiple metal types

- Measuring Range

- 0.1 mm to 100 mm

- Specimen Size

- Length: 10-100 mm, Diameter: 3-20 mm

- Accuracy

- 0.01 mm

- Gas Pressure

- 0.5-0.7 MPa

- Resolution

- 0.01 mm

- Operating Voltage

- 220V AC

- Power Supply

- 220V / 50 Hz

- Hardness

- Up to 60 HRC (detectable)

- Temperature

- 10C to 40C

- Test Range

- 0.1 mm - 100 mm

- Application

- Sorting and classifying metal parts (ex: fasteners, bearings, bolts)

- Max Height

- 1600 mm

- Humidity

- 85% RH (non-condensing)

- Response Time

- < 0.1 sec

- Usage

- Industrial Metal Sorting

- Capacity

- High-volume sorting

- Machine Weight

- 350 kg

- Test Speed

- Up to 200 pcs/min

- Test Width

- 130 mm

- Test Stroke

- Adjustable up to 100 mm

- Control Mode

- Automatic

- Data Logging

- USB Download/PC Connectivity

- Cable Length

- 2.5 m

- Service Requirement

- Annual calibration recommended

- Material of Construction

- Stainless Steel / Powder Coated

- Protection Rating

- IP54

- Input Hopper Capacity

- 20 liters

- Alarm System

- Visual & Acoustic

- Sound Level

- 70 dB

- Sorting Precision

- >99.5%

- Sorting Method

- Rotary Eddy Current Sensor, Pneumatic Actuator

- Consumables

- None (contactless testing)

About Eddy Current Sorter

Discover the fresh, new release of our Eddy Current Sorteran extraordinary solution engineered for dominant high-speed sorting of metal parts. Crafted with glorious stainless steel or powder-coated material, this industrial marvel boasts an input hopper capacity of 20 liters and a quiet sound level of 70 dB. With a rotary eddy current sensor and pneumatic actuator, it achieves outstanding sorting precision over 99.5%. Enjoy contactless, consumables-free testing, USB data logging, and robust IP54 protection. Make your operations glorious with this cutting-edge, fully automatic machine now under promotion!

Versatile Applications in Industrial Metal Sorting

The Eddy Current Sorter is designed for dynamic application places like factories, warehouses, and metalworking lines. Its advanced technology excels in sorting fasteners, bearings, and bolts, employing a non-contact rotary eddy current sensor for swift classification. The user-friendly interface ensures easy operation, making it ideal for usage in high-volume environments. Tailored applications range from precise quality control to automated batch sorting, establishing this machine as indispensable in a broad spectrum of industrial metal sorting tasks.

FOB Drop-off Details and Export Markets

Our Eddy Current Sorter can be arranged for FOB drop-off at major Indian ports, streamlining your transportation and delivery schedules. The main domestic market caters to leading manufacturing hubs across India, while principal export markets include Europe, Southeast Asia, and the Middle East. Asking price inquiries and further logistic details are managed through responsive customer support to ensure a smooth acquisition and setup, no matter where your business operates.

Versatile Applications in Industrial Metal Sorting

The Eddy Current Sorter is designed for dynamic application places like factories, warehouses, and metalworking lines. Its advanced technology excels in sorting fasteners, bearings, and bolts, employing a non-contact rotary eddy current sensor for swift classification. The user-friendly interface ensures easy operation, making it ideal for usage in high-volume environments. Tailored applications range from precise quality control to automated batch sorting, establishing this machine as indispensable in a broad spectrum of industrial metal sorting tasks.

FOB Drop-off Details and Export Markets

Our Eddy Current Sorter can be arranged for FOB drop-off at major Indian ports, streamlining your transportation and delivery schedules. The main domestic market caters to leading manufacturing hubs across India, while principal export markets include Europe, Southeast Asia, and the Middle East. Asking price inquiries and further logistic details are managed through responsive customer support to ensure a smooth acquisition and setup, no matter where your business operates.

FAQs of Eddy Current Sorter:

Q: How does the Eddy Current Sorter ensure high sorting precision?

A: The Eddy Current Sorter leverages a rotary eddy current sensor and pneumatic actuator to deliver sorting precision greater than 99.5%, ensuring accurate identification and separation of various metal parts.Q: What types of metal parts can be sorted using this machine?

A: This sorter is suitable for fasteners, bearings, bolts, and similar metal items ranging in length from 10 to 100 mm and diameter from 3 to 20 mm, making it a versatile solution for numerous industrial applications.Q: Where is the Eddy Current Sorter typically installed and used?

A: It is floor-standing and widely installed in factories, warehouses, and assembly lines where high-speed, high-volume metal sorting and quality control are essential.Q: What is the process for calibrating and maintaining the Eddy Current Sorter?

A: Annual calibration is recommended to maintain optimal performance. Minimal servicing is required since the machine is designed for contactless, consumable-free operation, ensuring low maintenance demands.Q: What are the benefits of automatic control and data logging features?

A: Automatic control facilitates seamless operation, while the data logging system allows users to download sorting data via USB or review it on a connected PC, enhancing traceability and process optimization.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Testing & Measuring Equipment Category

Universal Testing Machine

Application : Tensile, Compression, Bending, Shear, Peel tests on Metals, Polymers, Rubber, and more

Usage : Material Testing

Control Mode : Computer Controlled / Manual

Binocular Metallurgical Microscope

Application : Laboratory

Material : Metal

Color : Any

Product Type : Binocular Metallurgical Microscope

Usage : Laboratory

Control Mode : Manual

UV Intensity Meter

Application : Industrial

Material : Fiber

Color : Black

Product Type : UV Intensity Meter

Mpi Equipment

Application : Industrial

Material : Metal

Color : Any

Product Type : Mpi Equipment

Usage : Industrial

Control Mode : Manual

|

SUPERTECH SCIENTIFIC & METALLURGICAL SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry